Book Review: 'The Perfectionists: How Precision Engineers Created the Modern World'

Executive summary

Thumbs up.

The Perfectionists: How Precision Engineers Created the Modern World by Simon Winchester (also printed with the title Exactly) walks through the history of precision science, engineering, and manufacturing. If you're the kind of person who thinks that sounds interesting, you will not be disappointed. If you're not, you probably won't have even found this review on the personal blog of a random programmer.

Structure

The book is mostly chronological with occasional backtracking when jumping from the arc of one technology to another. For instance, it covers cars from the 1880s to the 1930s, but then backtracks a few decades to cover powered flight, etc.

Each section is labeled with an order of magnitude of accuracy. This is kind of fun and makes things real. It starts at 0.1 inches, then mostly goes down by factors of 1000 or so until reaching the atomic level.

Average length -- about 400 pages, or 9 hours by audiobook. The first 75% is a fascinating history of precision engineering from the mid-18th century to the mid-20th century. The next 15% starts focusing on nano-scale things and becomes less visceral. The last 10% is fine but seems out of place, as if it didn't obviously fit anywhere else.

Notes

The following are taken from my raw notes as I read the book, and so roughly follow the structure of the book.

First instance of tolerance

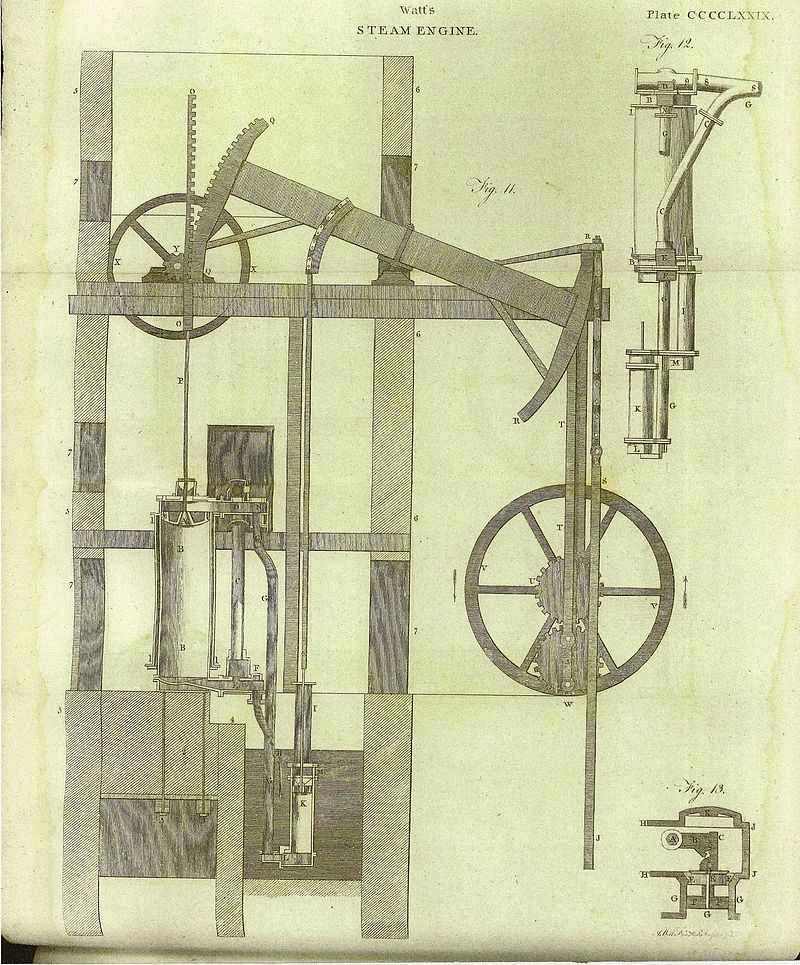

James Watt's steam engine, an improved version of the Newcomen engine, was among the first machines to demand precision manufacturing.

The piston had to fit snugly in the cylinder to maintain pressure. Watt had been relying on hand-hammered cylinders which were imprecise and leaky.

Watt met John Wilkinson, an industrialist and engineer who had invented a boring machine to make iron cannons. The same technology could be used to make precise cylinders for Watt's steam engine.

The first engine had a 50 inch cylinder with no gaps larger than the thickness of a shilling, about 0.1 inches.

Nature can be conquered; if we can but find her weak side.

This quote from Watt is interesting to me, because it conveys a sense of the universe as having hidden ways to be exploited. It reminds me of someone playing a videogame, looking for glitches in the physics engine.

Aside: 'special interests', 'on the spectrum'

A lot of the characters encountered in this book have a strong attraction to the aesthetics of precision for precision's sake. A lot also have other peculiar habits.

John Wilkinson, for instance, was obsessed with iron. He had his desk made from it. Iron coffins for himself to be buried in. An iron obelisk. He made the first iron bridge.

The author's father was a precision engineer, and the author mentions a lot of the people he encountered in that profession had similar quirks.

Machine tools

Henry Maudslay is the father of machine tools -- machines that help make other machines.

His story is a microcosm of the transition from traditional industry to the industrial revolution. There was a traditional apprenticeship period of 7 years which he started at age 15, but when his skill as a precise metalworker got around, Joseph Bramah of the Bramah Lock Company poached him, caring more about his skill than his credentials.

Bramah had a patent on the most unpickable lock of the era, but it was expensive to manufacture. Maudsley made a series of machines that made parts for the lock, reducing the need for skilled labor and making the lock economically viable.

Among Maudsley's most important contributions was the invention of the first practical screw-cutting lathe in 1800.

The creation of screws with standardized threads is the foundation of all subsequent precision machining, because it allows for repeatable, fine-grained adjustments. You can create machines where tiny, repeatable adjustments can be made by turning a screw. One turn might move a part by 0.01 inches, for example.

Again demonstrating the changing times, Maudsley left Bramah to open his own machine shop after 8 years after being denied a pay increase.

Industrial production

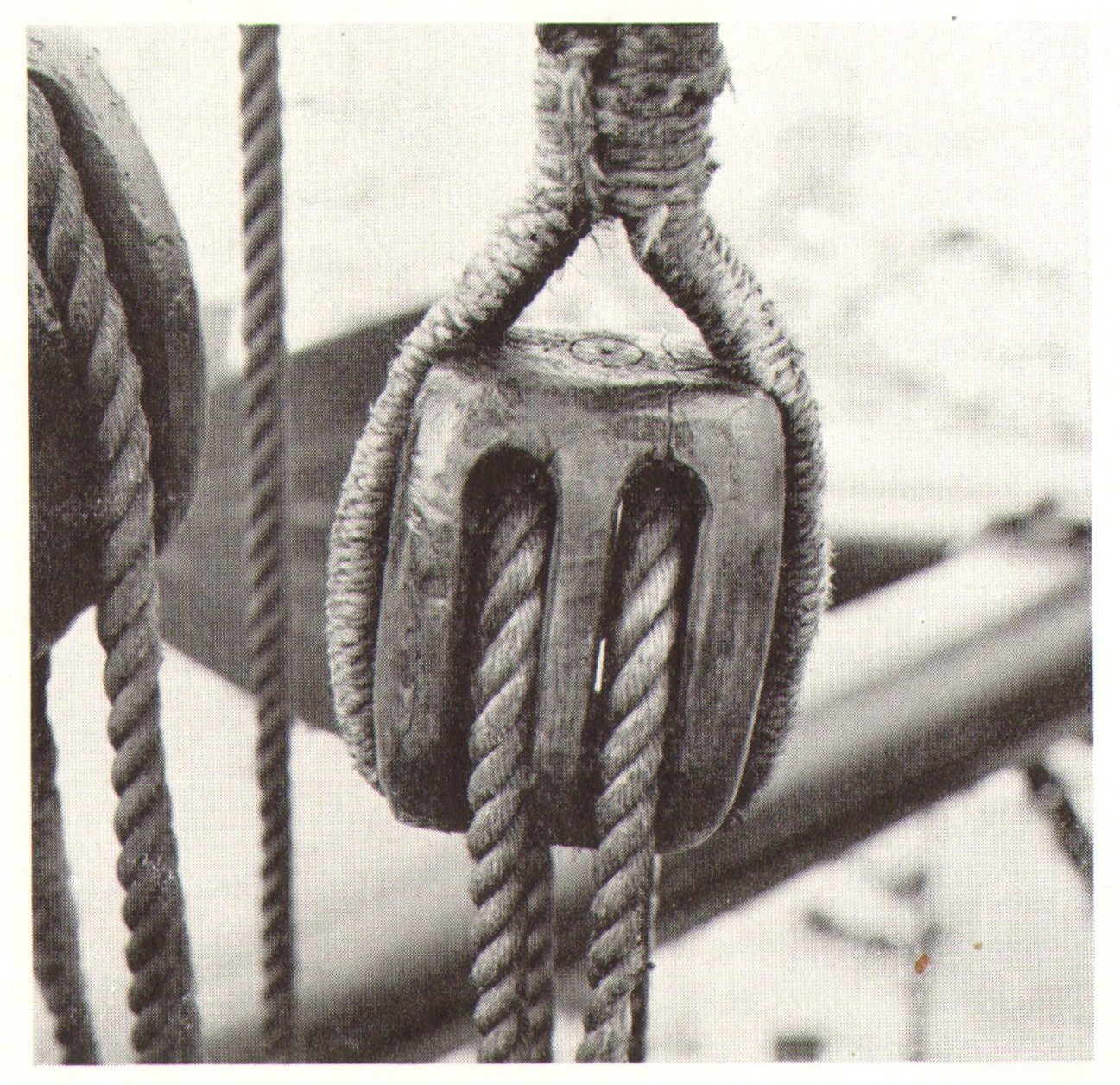

Maudsley's first major commission was to make a series of machines that could produce blocks for the Royal Navy. A block is a pulley used to raise and lower sails. Each British ship needed thousands to operate, and they were produced by hand by skilled craftsmen.

The machines were installed and enabled 10 unskilled men to produce the same output as 110 skilled craftsmen.

These consistent, high-quality, cheap blocks gave Britain a huge advantage in naval warfare, much needed in the Napoleonic wars that soon followed.

Interchangeable parts

You'll see a pattern here. The steam engine's success rested on the ability to make precise cylinders -- a technology developed for cannons. Some of the first industrial machines were used to make naval blocks. So too did the precision revolution get a push from gun-making.

Making guns with interchangeable parts would be a massive military advantage. In a world without interchangeable parts, fixing a gun would have a turnaround time of a few days by the regimental gunsmith. If a gun broke in the middle of a battle, as they often did, it was useless.

The idea was first developed in France in the mid-18th century, and demonstrated by Honoré Blanc in 1778. These muskets weren't made by industrial machines yet, but instead by skilled craftsmen who made the parts to a high degree of precision, but the parts were so precise as to be interchangeable, displaying the concept and value.

Unfortunately, the French Revolution resulted in the destruction of his workshop and the abandoning of the idea by France in the near-term.

Coincidentally, Thomas Jefferson was the American ambassador to France at the time, and was present for the demonstration. He wrote back to the US promoting the idea.

Unfortunately, the US granted the contract to Eli Whitney of cotton gin fame. Whitney was on the verge of bankruptcy and despite having no experience with gun-making, was granted the contract.

He talked about interchangeability, but secretly just had the guns made the traditional way. He had a few made to enough precision to fool the government during a demonstration, but it was mostly a sham.

This set back interchangeability of firearms by two decades.

19th century

The pace of innovation picked up, carrying into the core century of the industrial revolution we all learned about in school.

The author largely covers this development in the frame of the Great Exhibition of 1851, the first world's fair, held in London.

The exhibition was held in the Crystal Palace, a massive glass and iron structure built in a mere 6 months. It was filled with all the latest inventions and was a huge success.

The author focuses much of the section on one man, Joseph Whitworth. He was an apprentice to the master machinist Maudsley mentioned earlier, and was known at the time to be the best machinist in the world.

While he did produce final products, most notably the Whitworth rifle, he was more interested in the practice of precision engineering itself.

He was the first to develop a way to measure accuracy down to a millionth of an inch. He also pioneered the use of flatness as a measure of accuracy, with the first popular method of producing surface plates.

Additionally, he also popularized the idea of standardization of measurement. Machinists had been producing very fine work for decades now, but the parts were only precise relative to each other.

That is, a skilled machinist might produce a very nice bolt that fit snugly in a nut, but that bolt would not fit another nut produced by some other machinist. Whitworth popularized the idea of all these machinists producing parts that could be used together.

While much of the technology of the 19th century was invented in Britain, it was hastily adopted and improved upon in the United State. Whitworth, upon visiting the US, wrote:

The laboring classes are comparatively few in number, but this is counterbalanced by, and indeed, may be one of the causes of the eagerness by which they call in the use of machinery in almost every department of industry. Wherever it can be applied as a substitute for manual labor, it is universally and willingly resorted to. It is this condition of the labor market, and this eager resort to machinery wherever it can be applied, to which, under the guidance of superior education and intelligence, the remarkable prosperity of the United States is due.

Automobiles

Britain was behind France and Germany in the development of the automobile. Henry Royce owned an imported Decauville, but was unimpressed by its quality. He was a man who was single-mindedly obsessed with precision and perfection.

He rebuilt the Decauville, replacing almost every part with those of his own making. He eventually produced a few more. Charles Rolls encountered one and was impressed. He was an imported car dealer and implored Royce to go into business with him. Rolls was essentially a salesman who piggybacked on Royce's genius.

Rolls-Royce took one extreme of automobile manufacturing. Cars were made to extreme precision by skilled craftsman employing both traditional and modern techniques. Royce said he didn't want to expand production because that would entail compromising on quality. His motto was:

Whatever is rightly done, however humble, is noble

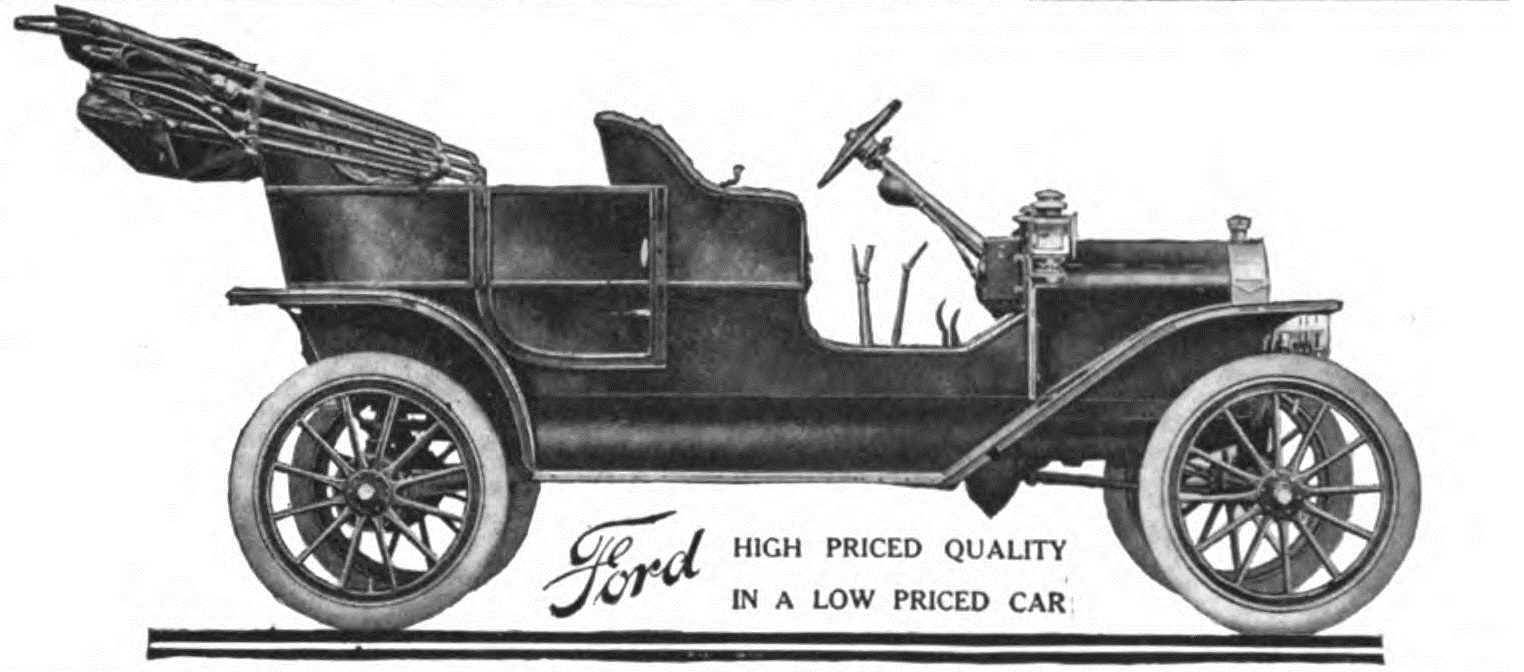

On the other end of the spectrum was Henry Ford, creator of the moving assembly line, producer of 16 million Model T automobiles.

It's not appreciated that assembly lines require interchangeable parts as a prerequisite. Rolls-Royce cars were extremely precise, but only to themselves. Each one was not perfectly identical to the next.

As a result of increasing efficiencies, Ford was able to reduce the cost of a Model T by a factor of 3 during its production.

Gauge blocks

The author uses this section to introduce the concept of gauge blocks, which are the foundation of all modern precision machining.

Gauge blocks are pieces of metal machined to extremely fine tolerance, and able to be stacked together to produce any desired length.

Ford imported ball bearings from a Swedish company. His engineers complained that they were the wrong size. The Swedish company insisted they were perfect, and used gauge blocks (invented by Swede Carl Edvard Johansson) to prove it. They were right and Ford was wrong.

Ford was so impressed, he hired Johansson to come to the US, and folded his company into Ford's.

Gauge blocks have an interesting property: they are so precise, the flat surfaces stick together due to molecular attraction. They can be stacked and moved around without any adhesive.

Aviation

As we get further into the 20th century, the book becomes somewhat less visceral due to the small scales. It's also more technologically divergent, whereas the previous bulk of the book was largely about finer and finer precision machining in industrial processes.

It discusses jet engine development at some length, but it's less about precision and more about the history of jet engines. It's still interesting, but not entirely in focus.

The author discusses the Qantas Flight 32 incident in some length as a way of demonstrating the extreme precision required in modern jet engines.

There was a neat bit about single crystal turbine blade manufacturing. Using the properties of how molecules bind together to do precision engineering.

Optics

Continuing the whirlwind that is the last quarter of the book, the author discusses the history of optics, but again it's less about precision and more about the history of optics.

One interesting bit here is that modern lenses can be produced that are precise to within the wavelength of the light they are focusing.

The author spends some time discussing the manufacturing errors of the Hubble Space Telescope, which was famously launched with a flawed mirror. The mirror was ground to the wrong shape because the machine used to measure, the null corrector, was improperly assembled.

The Hubble incident is a good example to discuss precision versus accuracy. The mirror was ground to extremely high precision, but it was not accurate.

The book then moves on to the manufacture of semiconductors using photolithography. This technique enables the production of transistors with features on the nanometer scale.

An interesting fact I learned is that modern extreme ultraviolet lithography can't use normal mirrors to direct light. At the extreme UV wavelengths, conventional mirrors would absorb too much of the light, so they have to use Bragg reflectors.

In addition to the machine being extremely precise optically, the clean rooms in which these chips are produced are among the cleanest places on Earth. They have a maximum of only 10 particles per cubic meter of size 0.1 microns, and no particles larger than 0.2 microns. For comparison, pharmaceutical clean rooms are more than 100 times less clean.

Wabi-sabi

The book ends with a few chapters that are somewhat out of place, as if they didn't fit anywhere else.

The first discusses the other side of precision, characterized by the Japanese concept of wabi-sabi.

Wabi-sabi focuses on the idea of imperfection and impermanence. The author goes on a tour of a Seiko watch factory which makes the most precise mechanical watches in the world, but which are still totally inferior in precision to modern quartz watches.

This chapter was interesting and pleasant but felt tacked on to the end of the book, without a clear place in the narrative.

SI units

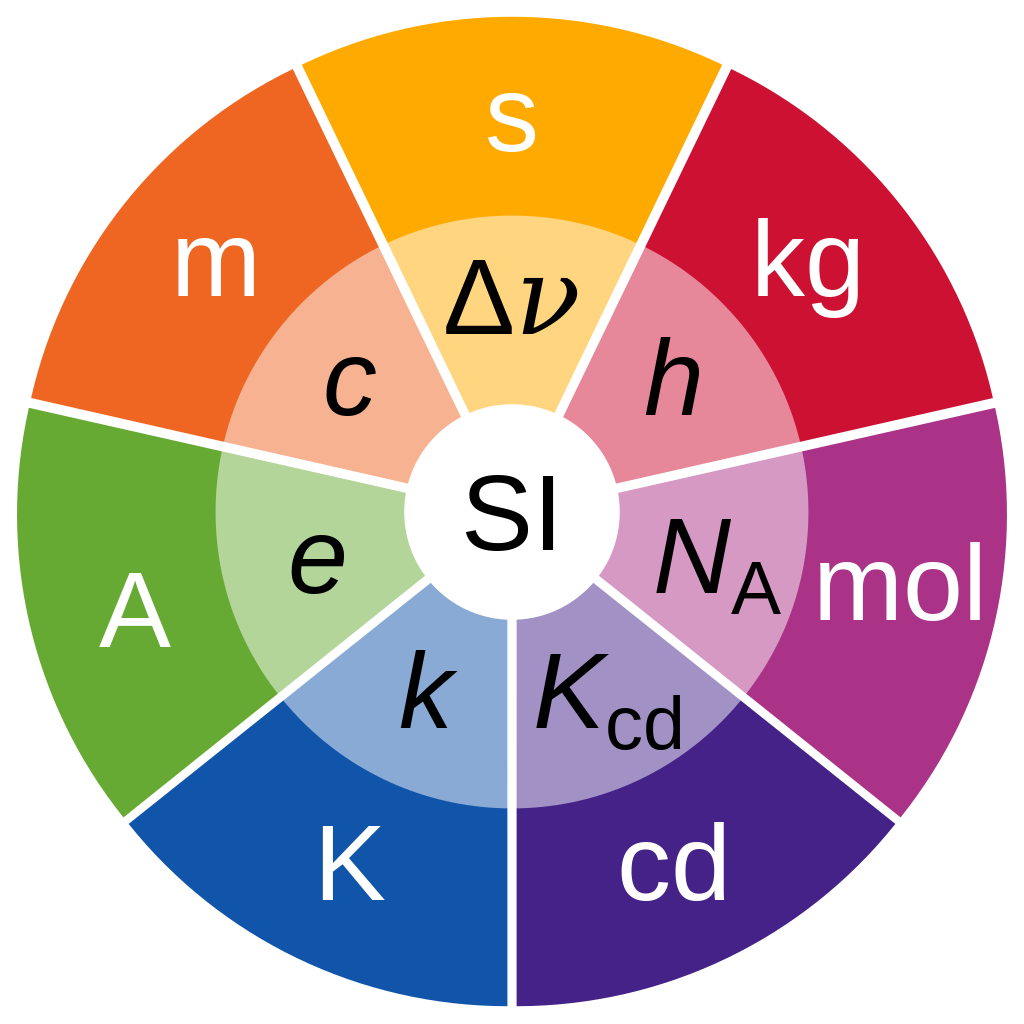

The author tells the history of the creation of the International System of Units, the modern metric system.

The really interesting part to me was the emphasis that the special part of the metric system is the way units are tied together. For instance, once you have defined the meter, you can define the kilogram as the mass of a cubic decimeter of water. And you can define the second as the oscillation of some pendulum of a certain length. Et cetera.

There is some discussion of how the units were periodically redefined in more and more foundational terms. For instance, the meter was originally defined by the length of a particular meridian of the Earth. This meter was then machined out of platinum and copies were distributed to the national institutes. But now the meter is defined in terms of the speed of light, but this definition requires a precise definition of the second, which is currently defined in terms of the oscillation of a cesium atom.

All units are now defined in terms of a set of 7 SI base units, which are defined in terms of physical constants.

The advent of atomic clocks also enabled the creation of the GPS system. This is relevant to the discussion above, because GPS uses time-of-flight of the radio signal, combined with extremely precise clocks, to determine position. In essence demonstrating the units of time and distance being bound together by the speed of light.

The author tells the story of the creation of GPS, which is interesting but also still lacks the feel of the rest of the book, because so many of the mechanisms are beyond the scale of human perception.

Conclusion

Overall, I enjoyed the book.

If the premise sounds interesting to you, you will like it. If the premise sounds dull, you probably won't.

It gave me an appreciation for how much the world depends on precision, and how this idea was foreign to most of human history.